Leather is a versatile and durable material that has been used for thousands of years. Before modern machinery and chemicals, leather was made using simple hand tools and natural ingredients. These traditional techniques allow leather to be produced off-grid without electricity or chemical tanning agents. This article provides a step-by-step guide to making and curing leather in a self-sufficient manner.

Gathering Tools and Materials

The first step is acquiring the necessary equipment and supplies:

Tools

- Knives for removing flesh and hair

- Scraper for scudding/dehairing

- Fleshing beam for stretching hides

- Awl and waxed thread for stitching

- Wooden mallets for softening

- Sandpaper for finishing

- Frames, racks or sawhorses for drying

- Smoking pit for curing (can be improvised)

Materials

- Animal hides

- Wood ashes for dehairing

- Lime for removing hair

- Tannins from bark or plants

- Brains, eggs or oils for tanning

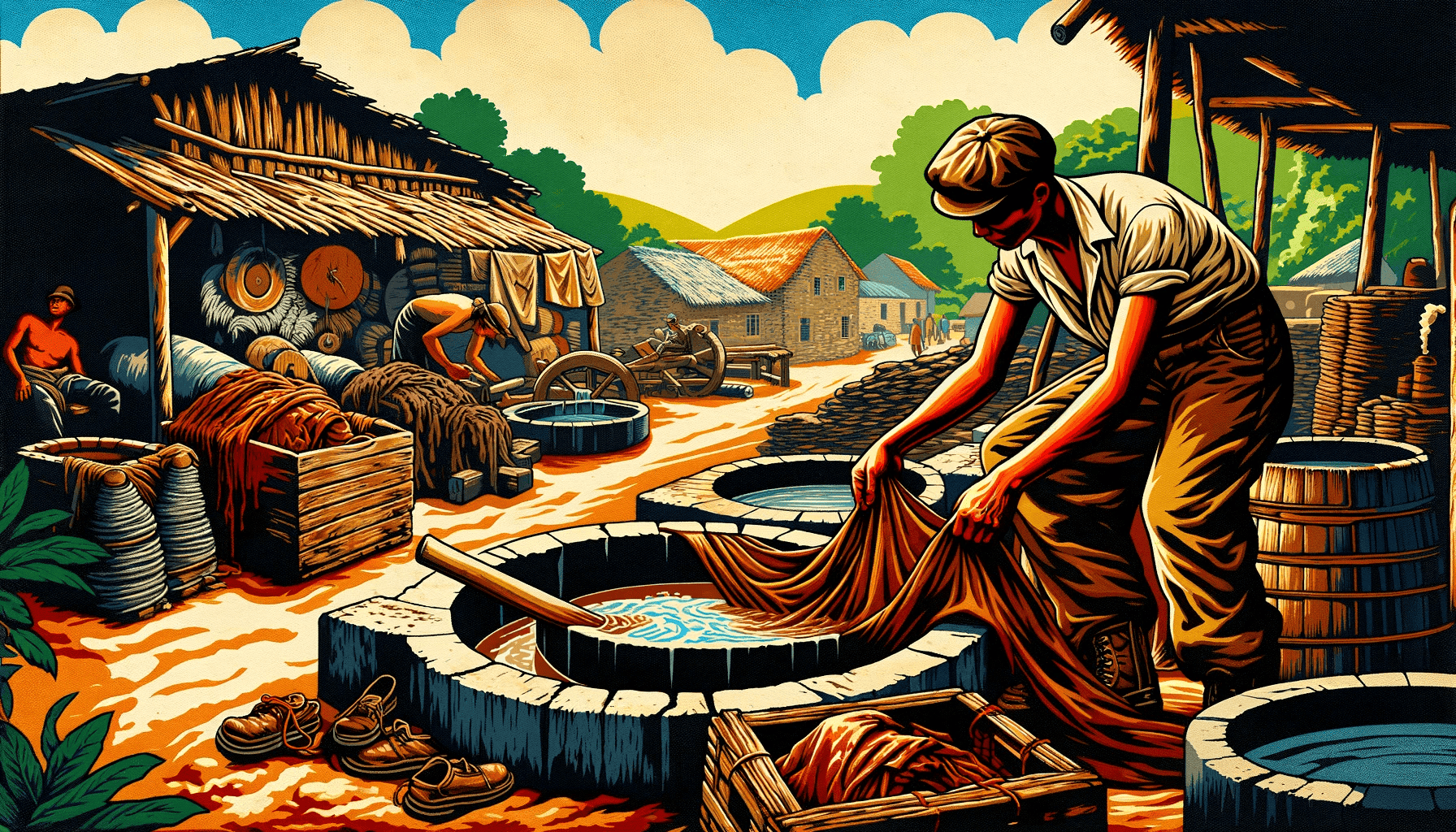

Pre-Tanning Hide Preparation

Before tanning, hides must be cleaned and prepared:

- Fleshing: Use a dull knife to scrape off tissue, fat and meat

- Liming: Soak hide in wood ash/limewater to remove hair

- Scudding: Scrape off any leftover flesh or fat

- Soaking: Rinse hide and soak in water for up to 2 days to rehydrate

Thoroughly cleaning hides prevents decay and allows tanning agents to penetrate.

Tanning the Hide

There are three traditional tanning methods using natural ingredients:

- Vegetable tanning: Soaking hides in tannin-rich vegetable solutions

- Brain tanning: Applying a paste of animal brains to convert hides into supple leather

- Oil tanning: Using oils like eggs, brains or neat’s-foot oil to tan hides

Tanning can take days or months depending on the process. This preserves hides and prevents them from becoming stiff.

Softening and Finishing

Additional steps create flexible, durable leather:

- Drying/smoking: Thoroughly drying hides on frames or racks. Smoking helps curing.

- Breaking: Softening through pulling, stretching and working the leather

- Finishing: Smoothening surface with sandpaper or burnishing tools

- Optional: Oiling or waxing for weatherproofing

With hand tools and patience, high quality leather can be produced sustainably.

Step-by-Step Process

Here is an overview of the full off-grid leather tanning process:

- Skin animal and collect hides

- Flesh, lime and scud hides

- Rinse and soak hides up to 2 days

- Tan using brains, eggs, oils or vegetable solutions

- Rinse and wring out excess liquid

- Stretch and dry on frames or racks

- Work leather vigorously to soften it

- Finish by sanding or burnishing surface

- Optional oiling/waxing for weatherproofing

- Smoke leather to help curing (optional)

- Enjoy homemade leather goods!

With practice, this traditional process allows self-sufficient leathercraft without electricity, machinery or chemicals.

Conclusion

Tanning leather using simple tools and natural ingredients is a lost art that allows for sustainable leather production off the grid. The process involves diligent preparation of hides, natural tanning agents, breaking and softening of the leather, and optional smoking or oiling. With some patience and experimentation, quality homemade leather can be crafted and enjoyed for years to come.